Magnetic Brakes Revolutionizing Efficiency Across Diverse Industries Through Cutting-Edge Technology

In the world of industrial technology, a new player is making waves – magnetic brakes. These innovative braking systems are promising to revolutionize operations across various sectors, offering unparalleled efficiency, reliability, and energy savings.

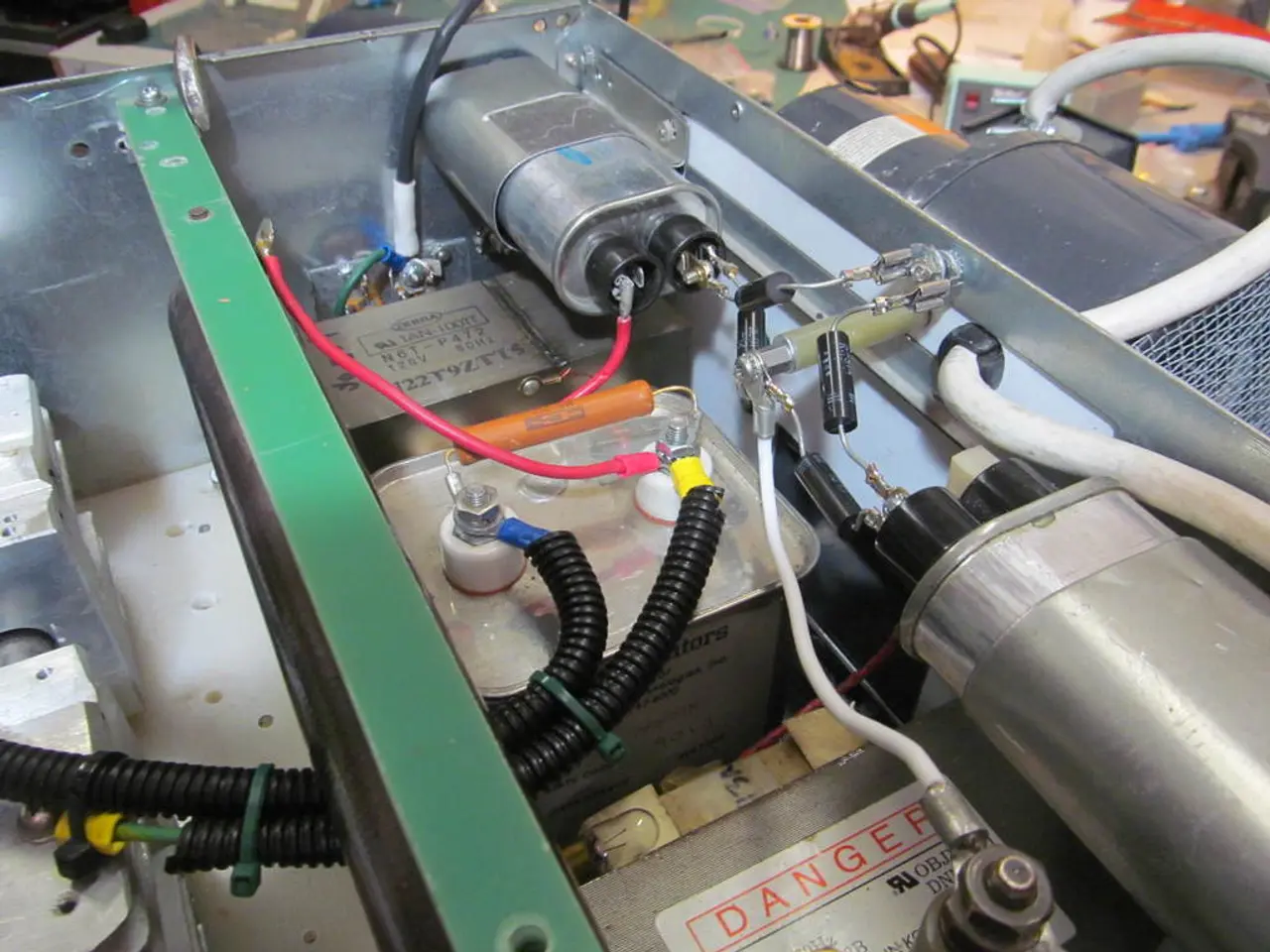

Magnetic brakes operate using magnetic fields to control and reduce motion, providing precise control over speed. Unlike traditional friction brakes that rely on direct physical contact, magnetic brakes convert electrical energy to mechanical energy directly, minimizing energy loss. This design results in less heat generation and consistent performance, especially in high-speed machinery, making them highly efficient.

One of the significant advantages of magnetic brakes is their low maintenance overhead. The non-contact operation eliminates the physical wear typical of traditional friction brakes, leading to longer service life and reduced maintenance intervals. This reduces downtime and operational costs, making magnetic brakes a cost-effective solution in the long run.

The versatility of magnetic brakes is another selling point. They can be integrated into various industrial settings, such as manufacturing equipment, metal fabrication, and even electric vehicles, where precise and responsive braking is essential. For instance, electromechanical braking systems, a form of magnetic-based braking, enable improved control, lower weight, and easier integration in EVs compared to traditional hydraulic brakes.

GRW, a leader in magnetic brake technology, has collaborated with a leading food processing company to equip conveyor systems with magnetic brakes. The result? A significant reduction in electricity bills and improved safety standards. GRW has also made a mark in other industries, streamlining production processes for a manufacturing giant and enabling machinery to start and stop smoothly, remotely, and precisely.

Embracing magnetic brake technology promises a future where industries thrive together, powered by advanced solutions that enhance performance and sustainability. With the integration of advanced control systems, magnetic brakes will operate with even greater precision and flexibility, monitoring real-time performance and adjusting settings to optimize efficiency according to changing demands.

Research into intelligent magnetic systems that can learn and adapt to varying conditions signals a new era in industry automation. With the right design, magnetic brake systems can be used in hazardous or explosive environments without posing a risk.

Making the switch to magnetic brake technology is an investment in the future of sustainability, economy, and safety. As a state-of-the-art technology designed to revolutionize operations, magnetic brakes offer significant economic benefits by minimizing energy usage and reducing the need for maintenance. A wide range of industries can benefit from the use of magnetic brakes, including manufacturing, logistics, food processing, and more.

In conclusion, magnetic brakes generally offer higher efficiency, lower maintenance, and unique versatility advantages compared to traditional friction brakes, making them suitable for various industrial applications. As the industry continues to evolve, the adoption of magnetic brakes is poised to become a key driver in enhancing industrial performance, sustainability, and safety.

[1] Magnetic Brakes: A Comprehensive Guide. (2021). Retrieved from https://www.grw.co.uk/magnetic-brakes-a-comprehensive-guide/

[2] The Advantages of Magnetic Brakes in the Modern World. (2021). Retrieved from https://www.grw.co.uk/the-advantages-of-magnetic-brakes-in-the-modern-world/

[3] Magnetic Brakes in Electric Vehicles. (2021). Retrieved from https://www.grw.co.uk/magnetic-brakes-in-electric-vehicles/

The integration of magnetic brake technology in industrial settings, such as manufacturing and food processing, can lead to significant energy savings and improved safety standards, as demonstrated by GRW's collaborations.

Advances in data-and-cloud-computing can enable magnetic brakes to operate with even greater precision and flexibility, optimizing efficiency according to changing demands in the technology-driven industrial landscape.