Mandatory Copper Wrapping Coating for Printed Circuit Board (PCB) Fabrication

In the intricate world of printed circuit board (PCB) manufacturing, a lesser-known yet crucial process is gaining attention – copper wrap plating. While the term "copper wrap plating" may not be widely used, its principles are essential for enhancing PCB performance and reliability.

This process, often referred to as edge plating or similar techniques, encapsulates the edges of PCBs, providing several benefits that can significantly impact a board's overall efficiency and longevity.

One key advantage of copper wrap plating is its role in electromagnetic interference (EMI) shielding, a crucial aspect for high-frequency designs. By reducing the impact of electromagnetic radiation, this shielding ensures the circuit board performs optimally in a variety of applications, from telecommunications to wireless devices.

Another benefit is the improved chassis ground connection, which is vital for maintaining electrical integrity and safety. The encapsulation of the edges enhances this connection, providing a more robust and reliable system.

Moreover, the plating of edges can offer additional structural integrity and uniformity, ensuring consistent performance across the PCB. This consistency is particularly beneficial in multi-layer PCBs, where it can help prevent delamination and strengthen the board's structural integrity.

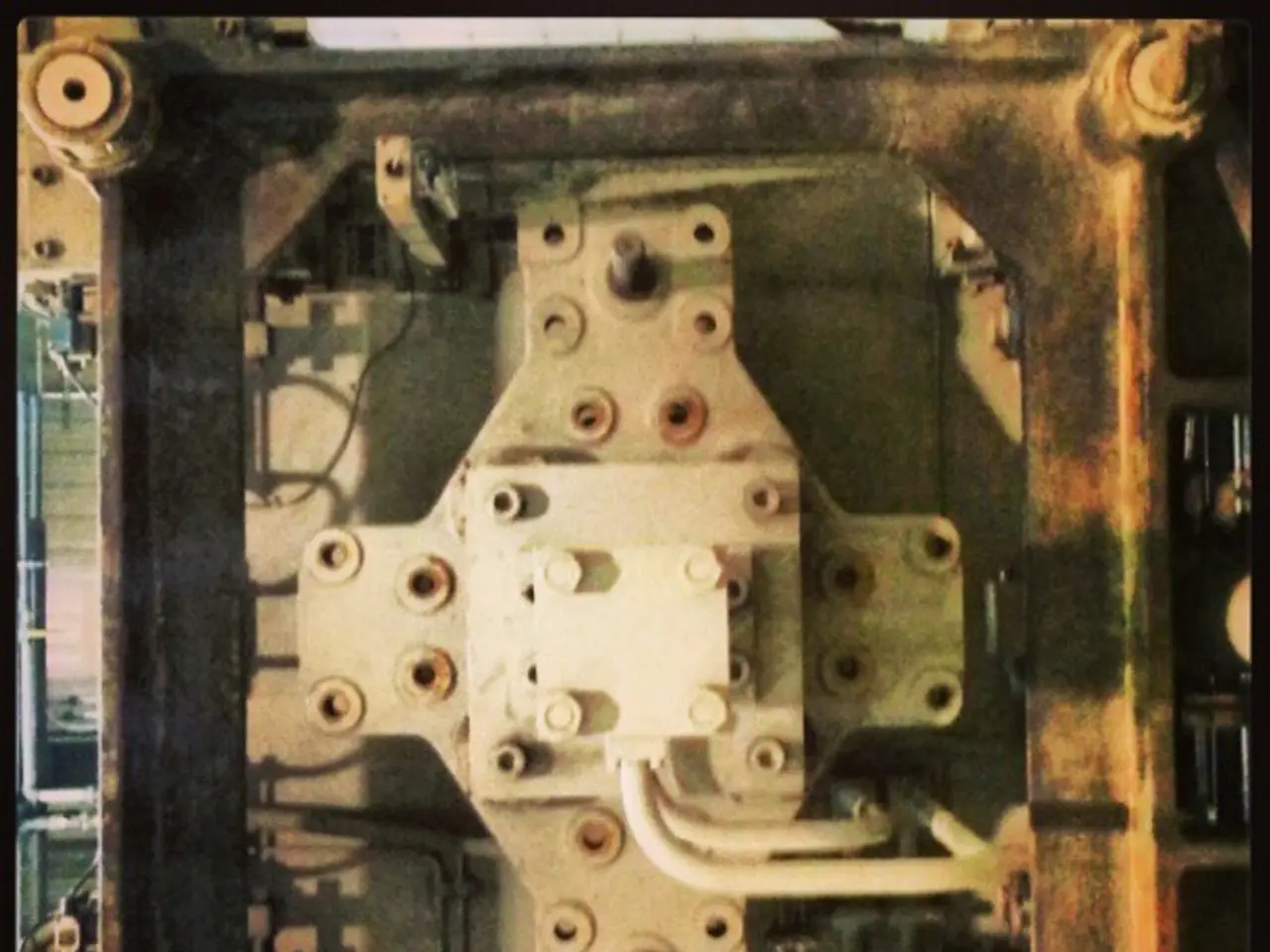

Copper wrap plating is not just beneficial for the edges of the PCB; it can also be implemented for buried vias if they are applied in separate layer stacks. Filled copper wrap structures can be formed by applying a continuous copper film to the interior of a via or by having a separate pad formed around the via ends.

The continuous minimum wrap requirement for class 3 designs is 0.472 mils for a via, 0.236 mils for a microvia, and 0.276 mils for a buried via. The IPC 6012B standard specifies that copper wrap plating shall be continuous and extend a minimum of 25 microns where an annular ring is required.

Vias that end closer to the outermost layer of the board are more likely to fracture under thermal cycling. Repeated thermal cycles can lead to stress on the plating, via fill materials, and laminate interfaces in PCBs due to expansion mismatch. However, the copper wrap plating forms a butt joint between the via pad and the copper fill plating, increasing the contact area between the via plating and the annular ring, and potentially reducing the risk of fracture.

The copper wrap plating requirement enhances the reliability of the via plating and can potentially minimize failure due to cracks or separation. Button plating over the existing copper wrap plating can further enhance the structural integrity of the via wall.

In conclusion, while "copper wrap plating" may not be a standard term in PCB manufacturing, the principles of edge plating can apply to similar processes that enhance PCB performance and reliability. PCB designers should be familiar with this technique as a way to increase the reliability of via structures, optimize the PCB manufacturing process, and increase production yields while ensuring enhanced product life.

A material selector for PCB manufacturing may consider data-and-cloud-computing technologies to identify suitable processes for electromagnetic interference (EMI) shielding and improved chassis ground connection, such as copper wrap plating or similar edge plating techniques. This technology can contribute to a board's structural integrity, uniformity, and performance longevity by providing additional structural support and reducing the risk of fracture in via structures.