Mastering Essential Sheet Metal Work: Comprehensive Guide for Beginners

In the realm of customized fabrication services, Heather & Little stands out as a trusted name for high-quality sheet metal products. This article takes a closer look at the intricate process behind their offerings.

The sheet metal fabrication journey begins with a design that outlines the shape, dimensions, and function of the final product. This initial step sets the stage for the subsequent stages of cutting, bending, and finishing.

During the cutting stage, various techniques are employed to shape the raw metal. Common methods include laser cutting, waterjet cutting, plasma cutting, oxy-fuel cutting, mechanical cutting (such as sawing, shearing, and milling), punching, and nibbling. Each technique offers unique advantages, with laser and waterjet cutting providing precision for fine details, while plasma and oxy-fuel cutting excel in handling thick metals. Punching and nibbling are swift methods favored in mass production, but they require post-processing for burr removal.

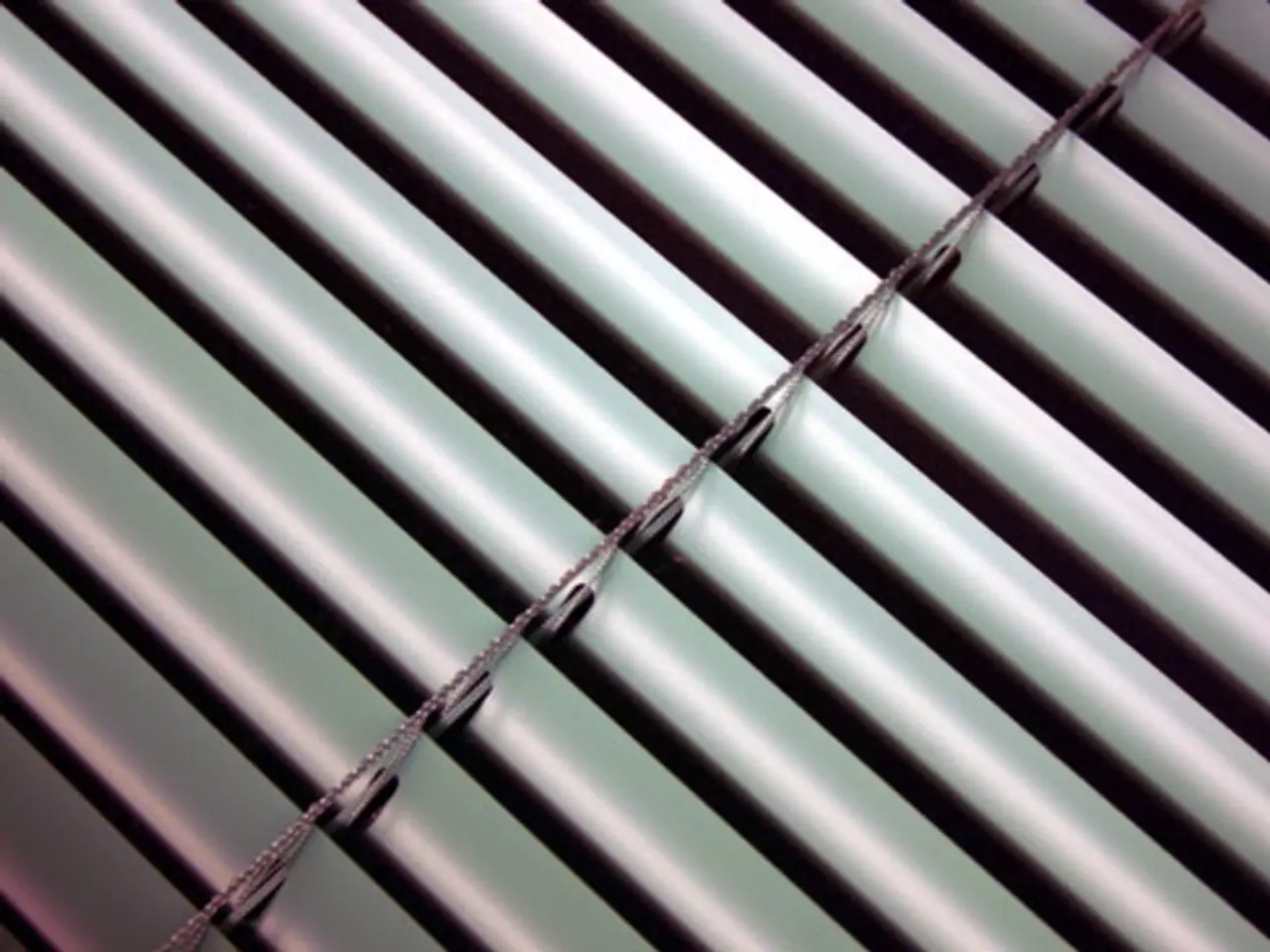

Following the cutting stage, the metal is shaped into the desired form using press brakes or rollers during the bending process. Press brakes precisely bend metal sheets into angles or curves via computer numerical control (CNC), ensuring consistent, programmable bends. Plate rolls roll flat sheets into cylindrical or curved shapes. These methods maintain the metal's structural integrity by controlling bend radii and bend allowances during design.

The final step in the sheet metal fabrication process is often finishing, which can include polishing or coating the metal to ensure durability and meet aesthetic standards. Finishing techniques include deburring, grinding, polishing, coating (painting, plating, powder coating), and sometimes heat treatment. These steps refine edges, improve surface finish, and protect the metal. For example, post-cutting burr removal is necessary after punching or nibbling due to uneven edges.

Heather & Little's team has extensive experience in creating precise, durable, and aesthetically pleasing sheet metal products tailored to specifications. Their offerings range from lightweight, corrosion-resistant aluminum, celebrated for its use in automotive and aerospace applications, to stainless steel, renowned for its strength and resistance to rust, commonly used in medical devices, kitchen appliances, and architectural elements.

The adaptability of sheet metal fabrication allows it to meet the unique needs of various industries, such as construction, manufacturing, energy, electronics, and transportation. Applications are diverse, ranging from crafting custom panels for construction to producing precision components for machinery. This durability results in long service lives for sheet metal components, reducing the need for frequent replacements.

In industries where aesthetics are paramount, finishing techniques are essential. For instance, these techniques are crucial for applications like decorative architectural elements. To learn more about Heather & Little's sheet metal fabrication services, contact their shop.

[1] Sheet Metal Fabrication Techniques and Applications. (n.d.). Retrieved from https://www.sciencedirect.com/topics/engineering/sheet-metal-fabrication

[2] Sheet Metal Fabrication Process. (n.d.). Retrieved from https://www.machinistworld.com/topics/sheet-metal-fabrication-process

[3] Sheet Metal Fabrication Processes. (n.d.). Retrieved from https://www.machiningcloud.com/en-us/blog/sheet-metal-fabrication-processes

[4] Sheet Metal Fabrication Techniques. (n.d.). Retrieved from https://www.machiningcloud.com/en-us/blog/sheet-metal-fabrication-techniques

[5] Sheet Metal Fabrication: Process and Techniques. (n.d.). Retrieved from https://www.thomasnet.com/articles/manufacturing/sheet-metal-fabrication-process-and-techniques/

Read also:

- Adjusted logistics being influenced by the recent manufacturing procedures

- Crucial Safety Elements in Tractor Blueprint Development

- Rapid Growth Projected for the Liquid Silicone Rubber Market, Anticipated to Reach a CAGR of 9.2% by 2034

- Projected expansion of the Center Stack Display Market to reach USD 7.2 million by 2034 predicted